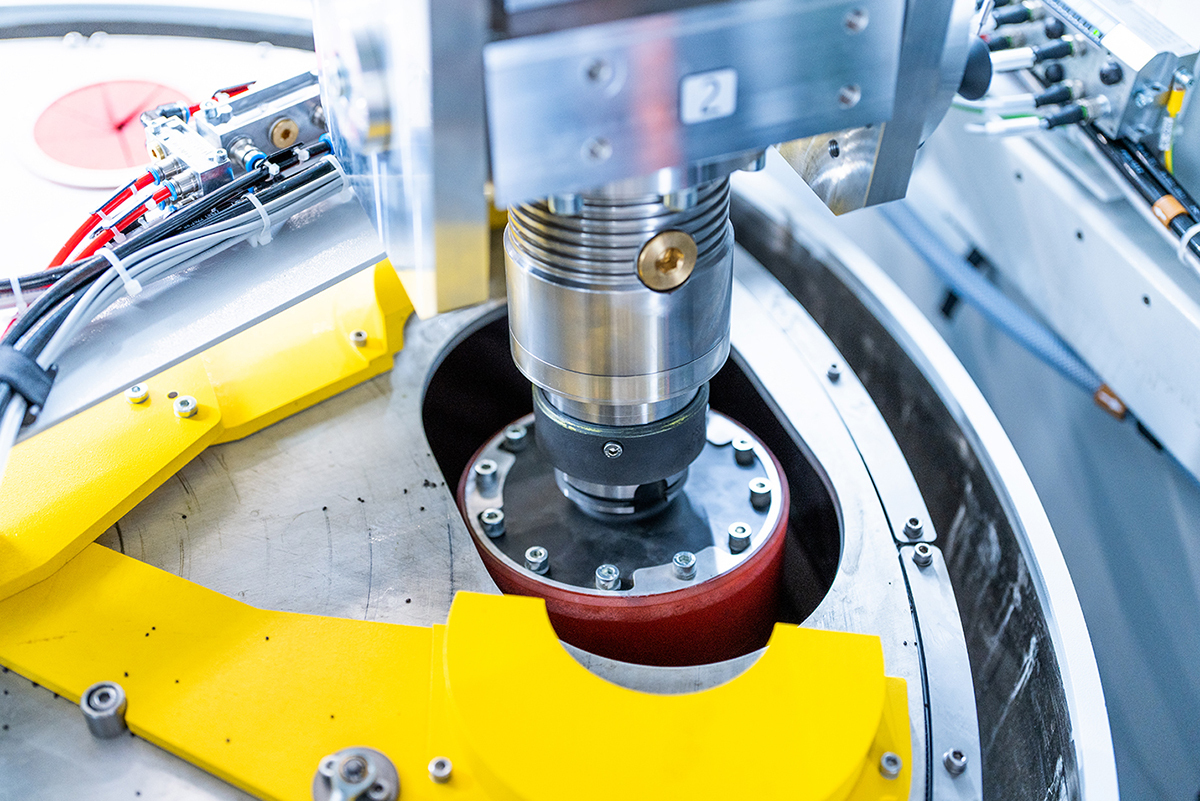

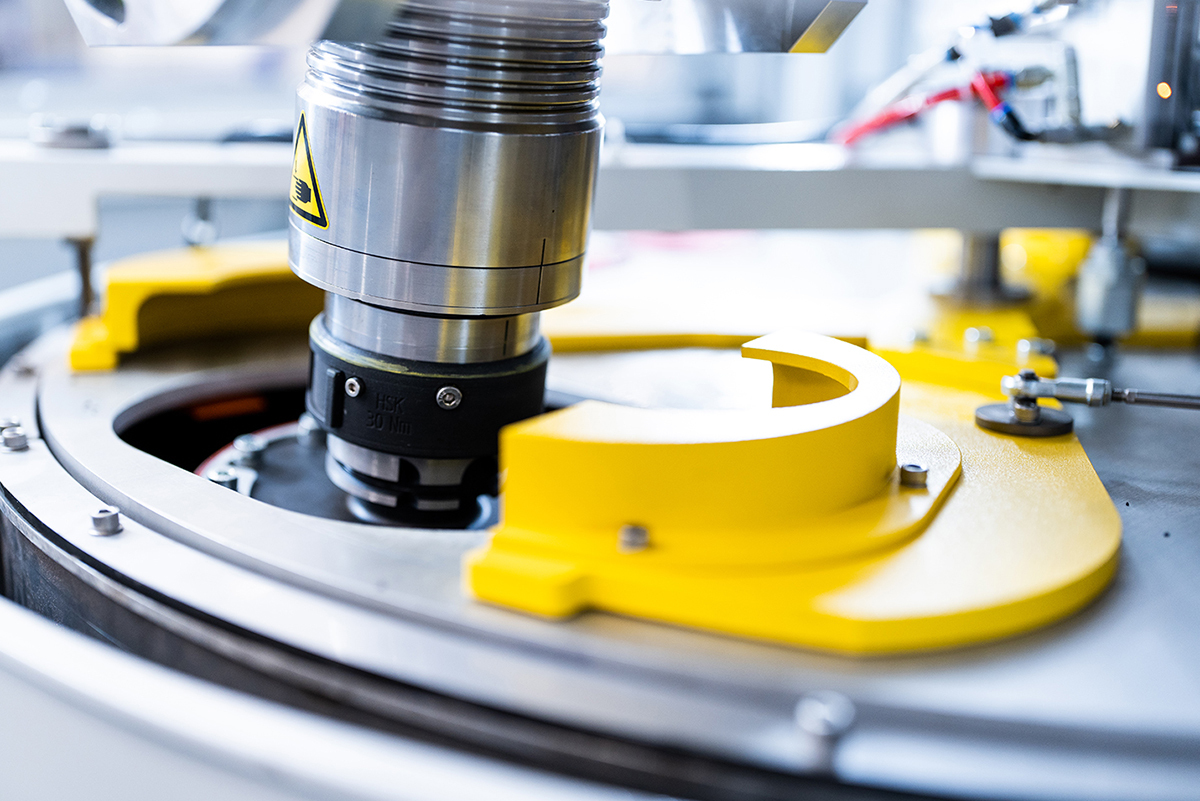

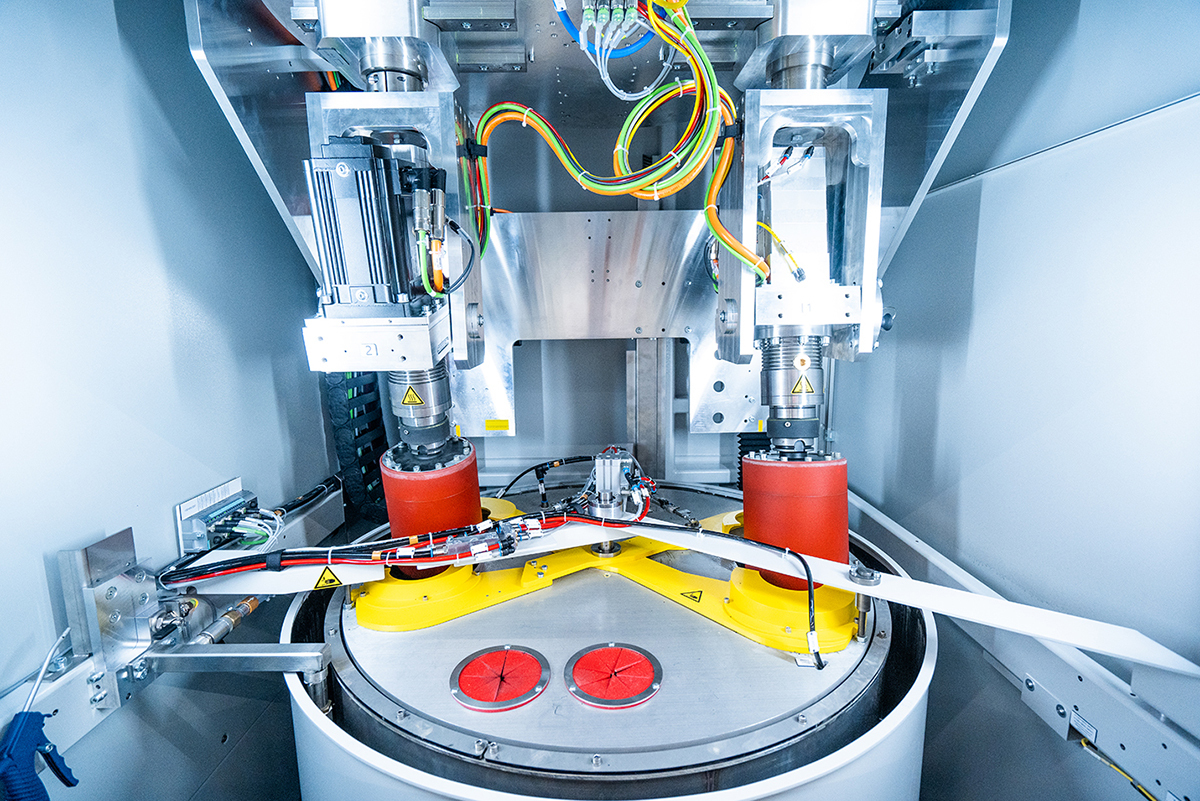

The SF Manual series of machines can optionally be equipped with pulse finishing and because loading is carried out manually, they are suitable, among other purposes, for small-scale series production and production lines without a predefined cycle time. Typical applications for the SF Manual series include deburring, rounding, smoothing and polishing of gear wheels, turbine blades, worm drives and for the selecting rounding of the cutting edges of cutting tools.

MANUAL WORKPIECE LOADING

Automatic door at the front of the machine enables a fast and easy manual changeover of workpieces.

PERFECT FINISHING RESULTS

The SF enables several stages of processing to be carried out very quickly in a single operation. For example, a workpiece can be successively deburred, edge-rounded, smoothed and polished in one operation. The position-controlled movement sequence enables individual parts of a workpiece to receive intensive selective finishing. Thus the amount of material removed can be regulated right down to the µm level.

VERY SHORT PROCESSING TIMES

Tremendous processing force and high stream speeds result in extremely fast and economical finishing of the workpieces.

CUSTOMIZED SOLUTIONS

Number and design of workpiece holders can be customized to suit requirements. Depending on your needs, we carry out individual adjustments or develop a customized solution based on your requirements.