Speed, processing time, water-compound concentration, rinse cycles and all other important process parameters can be set via simple menu navigation using Siemens touchscreen control, and up to 5 000 different machining programs can be stored.

HOW DOES THE DISC FINISHING PROCESS WORK?

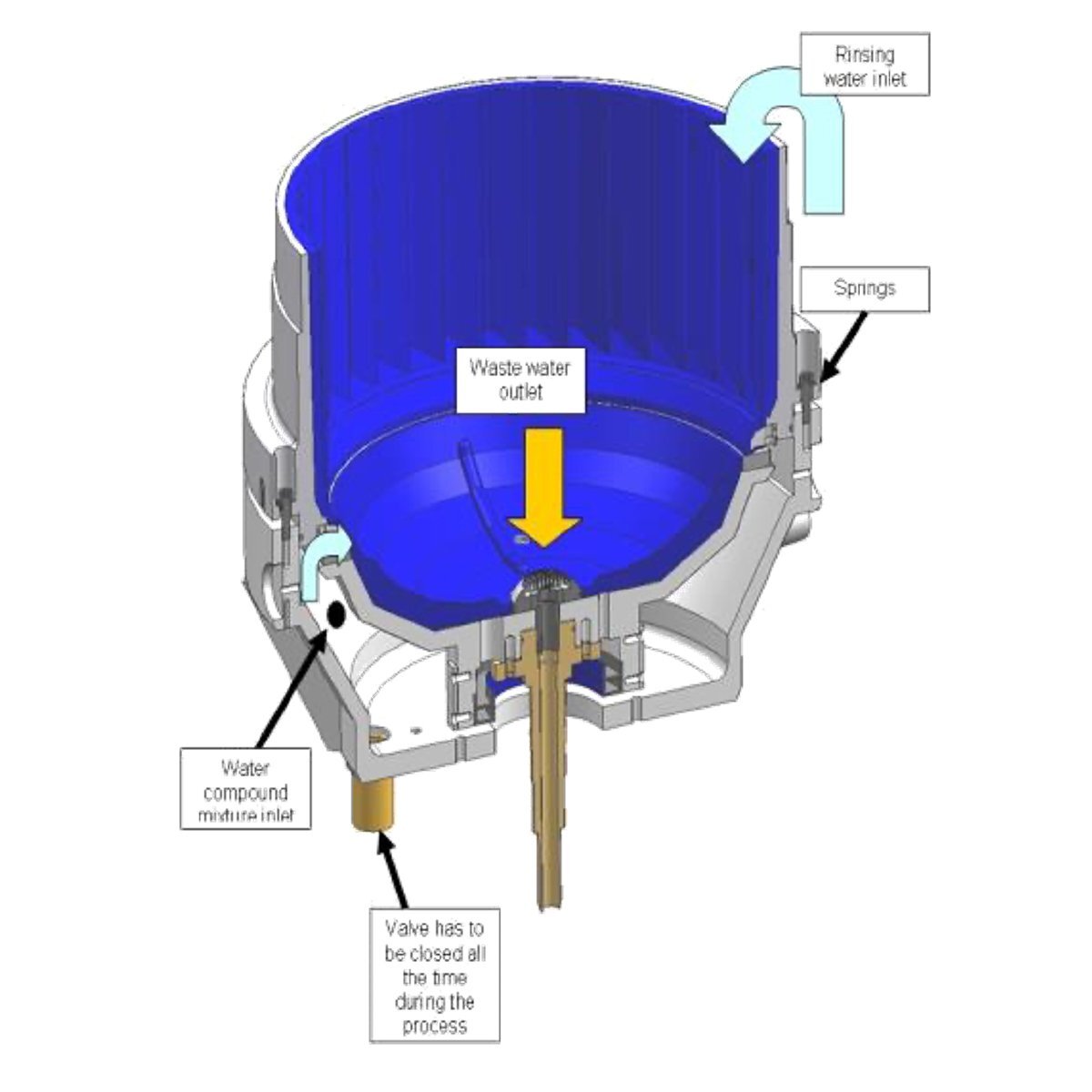

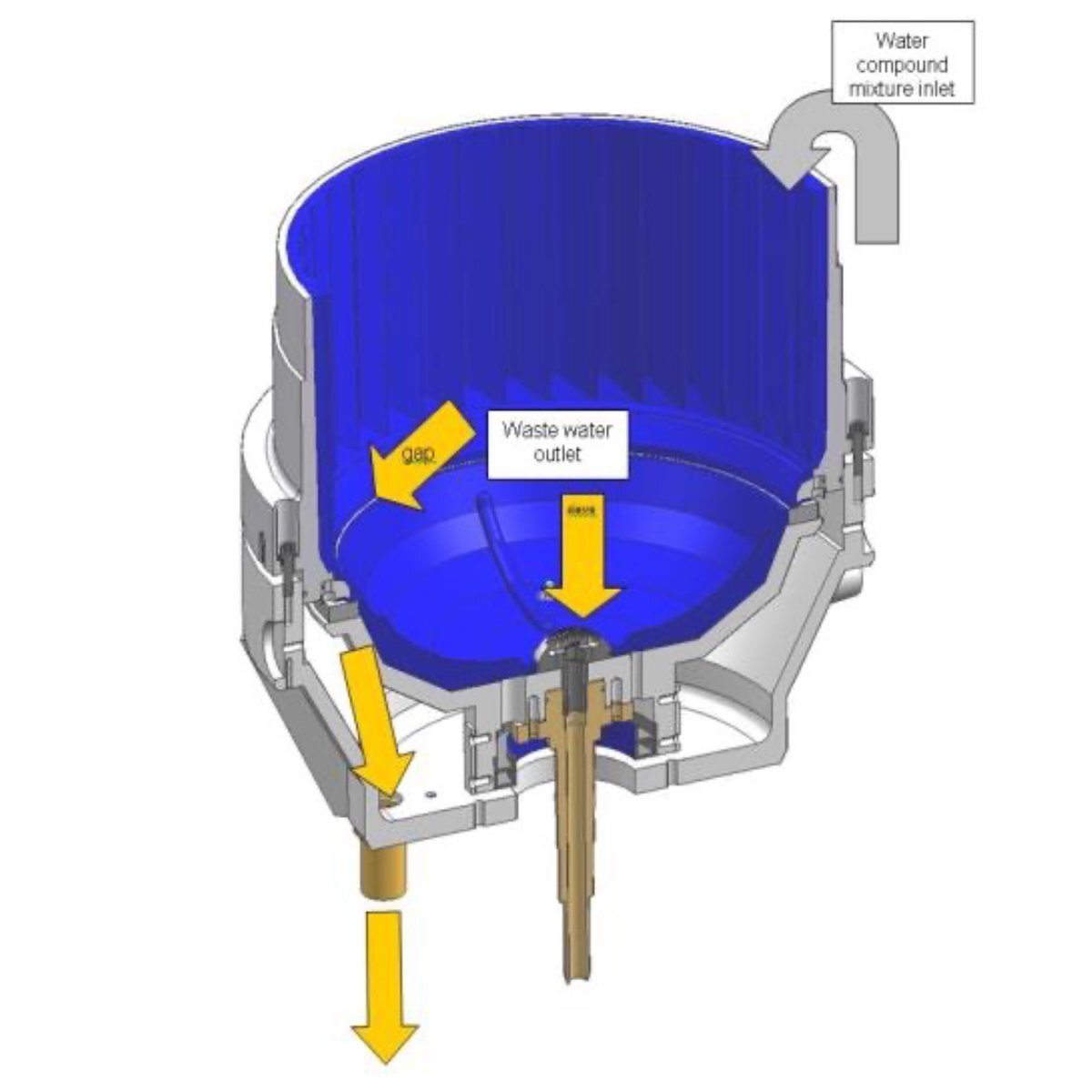

- It involves a vertical cylindrical process container, where the container floor (the so-called disc) is separated from the container wall by a gap.

- When the disc turns, the material on top of it is catapulted outward by the centrifugal force and is decelerated on the fixed container wall, therefore forming the characteristic toroidal shape of the grinding bodies and workpieces mixture.

- The shape of the disc, container and gap area is crucial for minimal processing times and simultaneously gentle processing.

- The process is mainly used for the processing of smaller parts and, due to the high rotation speed, has the advantage that processing times can be reduced by a factor of 6 to 10 compared to vibration systems.

Easiest operation

Absolute reliability

The consistent use of only the highest-quality materials and components ensures trouble-free operation and a long service life.

Highly cost-effective

Comparatively low acquisition costs and a high potential for savings in processing times certify the CF-Series an excellent price/performance ratio.

Perfect processing results

Deburring, smoothing, grinding and polishing, the entire program using a single machine.

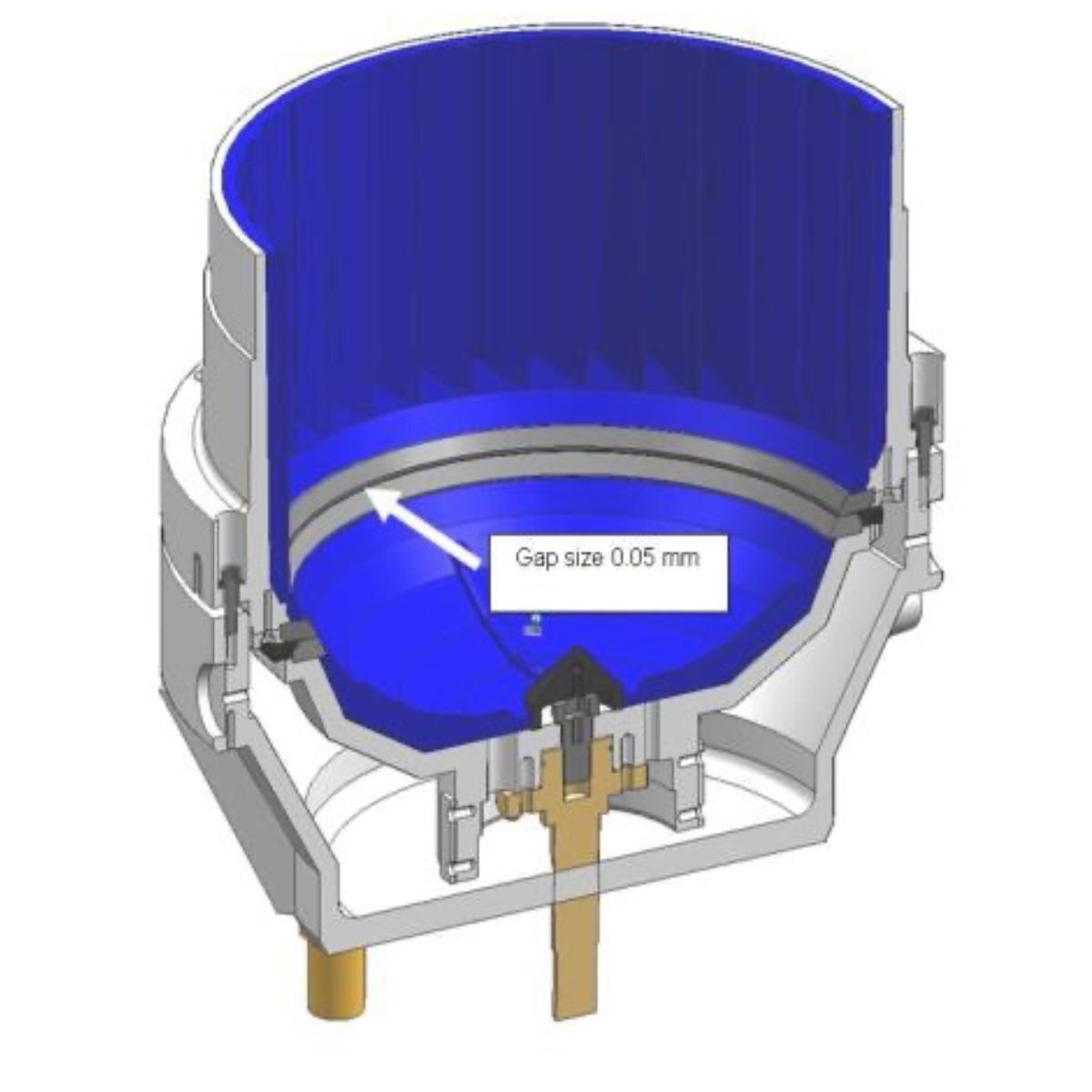

At the heart of every disc finishing machine is the gap between the container and the disc. The gap is very important as it has to fulfil several functions. For example, mass finishing stones and workpieces should be prevented from penetrating it and at the same time, the waste water should be able to flow out easily. The gap should remain stable over time and should preferably not wear out. OTEC has the right gap system for every challenge: wet processing, dry processing and the patented zero gap system for extremely thin and intricate parts. Using a ring made of hard SiC ceramic, the gap remains dimensionally stable even when heat is generated and is extremely wear resistant.

Our zero gap system is unique

The gap between the revolving disc and the stationary container can be reduced to nothing for wet processing of very thin workpieces. Using fine-grained abrasive such as quartz is therefore made possible and prevents the workpieces from becoming jammed in the gap.

The different gap systems guarantee perfect processing:

The gap size can be set to precisely 0.05 mm using this system since two ceramic rings made of SiC form the gap. This technology is preferred for dry processing as it enables the use of very fine polishing granulates for the best polishing results.