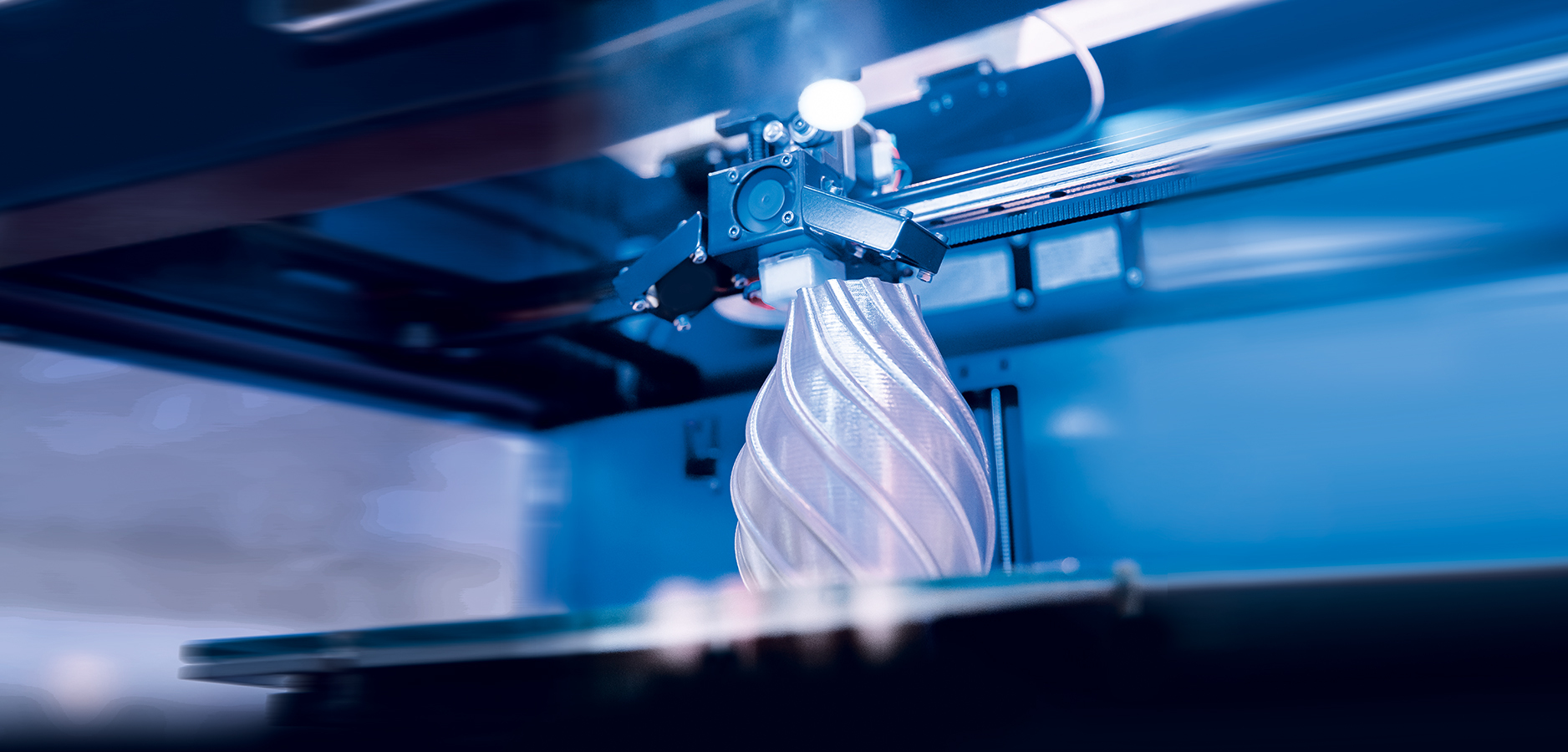

3D printing has its own specific challenges: process complexity and stability, automation, and the additive surface structure itself. These include removing the support structures as well as reducing waviness and micro-roughness. Post-processing therefore plays a key role in the future of additive manufacturing across all sectors.

Application areas

- Small and large ceramic, plastic and metal components weighing up to 200 kg

- Complex and bionic structures, whatever the printing process

- Optimising the look, feel and performance of surfaces (scratch and dirt resistant)

- Surface levelling and smoothing for a matt or high-gloss finish

- Tribological surface optimisation

Advantages of the OTEC post-processing solutions

- Cost-effective solutions: minimise post-processing costs

- Efficient technology: reduces roughness and waviness in minimal time

- Customised processes: solutions for both functional components and high-tech applications

- All in one machine: deburring, removing waviness, reducing roughness and surface polishing

- Rationalise and automate post-processing

- Easy to integrate in existing process chains

- Ergonomic, all-in-one modular machine concepts designed for all applications from small batches to series production